A Revolutionary Step in Sustainable Construction

a cementitious binder reducing more than

80 % of CO2

ecobinder SOLUTIONS is the world's first supplier and producer of a cement-free, special ecobinder specifically engineered for the drymix industry.Our innovative binder system dramatically reduces carbon emissions cutting the carbon footprint by more than 80% compared to traditional Portland cement-based solutions.

Why choose

ecobinder SOLUTIONS?

"smarter, greener, stronger"

As pioneers in sustainable construction materials, we are redefining the future of building by offering high-performance, eco-friendly alternatives that do not compromise on strength, durability, or versatility.

100%

Portlandcement

Free

80%

Reduced CO2 tons

delivery

Supply in bulk truck and Super Sacks

reducing carbon footprint by more than 80 %

Our ecobinder reduces CO2 emissions by more than 80%.

global cement manufacturing produced

1.6 billion metric to. of CO2 in 2022

about 8% of the world's total CO2

emissions

key benefits ecobinder

🌱 Zero Portland Cement

lower carbon footprint

🌱 Superior Performance

high adhesion, durability, and strength

🌱 Eco-Friendly

significant CO₂ reduction

🌱 Versatile Applications

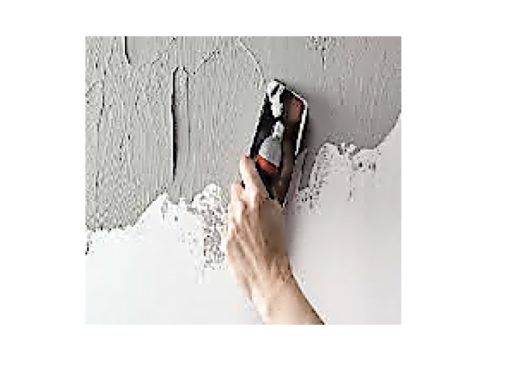

ideal for tile adhesives, grouts,repair mortar, self-leveling underlayments etc.

🌱 3 Types - ST - standard - FS - fast set - WH -white

🌱 Regulatory Compliance

meets stringent environmental and technical standards

innovative solutions

- eliminates the use of Portland cement

- significantly reducing CO₂ emissions

- ensures strength, durability, and workability comparable to traditional binders

- helps manufacturers meet sustainability goals without sacrificing performance

advanced technology

ecobinder

The “Green” Cement Alternative for Dry-Mix Applications

ecobinder is a next-generation, sustainable binder engineered specifically for the dry-mix industry. It offers a stable and eco-conscious alternative to traditional Portland cement without compromising on performance.

Designed to meet the highest standards in modern construction.

ecobinder delivers:

- accelerated setting for faster workability and reduced project timelines

- high early strength development at 6, 16, and 24 hours

- consistent strength gain over time, ensuring long-term durability

- shrinkage compensation, minimizing cracks and enhancing dimensional stability

- better adhesion , reduced addition of polymer powders

Whether you're producing tile adhesives, grouts, screeds, or repair mortars, ecobinder offers the green performance you can rely on-every time

carbon footprint cement

Ordinary Portland Cement (OPC) has a high embodied CO₂ footprint, largely due to the calcination of limestone and energy-intensive production.

ecobinder is designed from low-carbon alternatives such as:

- fine ground Granulated Blast Furnace Slag (GGBS)

- ·different activators

- ·recycled fillers and by-products

ecobinder can reduce CO₂ emissions up to 80%

mismatch Dry-Mix demand and cement producer

dry-mix industry's demand is relative small in volume and high in specialization. Cement plants operate at massive scales andare not flexible enough to produce customized cement compositions for such niche applications.

ecobinder empower dry-mix producers to take control of binder chemistry

availability pure cement

Cement manufacturers typically no longer supply pure groundclinker without additives (e.g. limestone, pozzolans, calcined clayetc.), making it difficult for dry-mix producers to formulate consistent, specialized products.

ecobinder allows precise control over phase composition and additives, ensuring tailored reactivity and hydration

consistency

In dry-mix systems, especially those requiring precise open time, pot life, and curing behavior, variability in setting times andstrength development due to changing cement compositions is unacceptable.

ecobinder is based on engineered raw materials with tight quality control, eliminating batch-to-batch variations

drymix industry neads

high early strength & shrinkage compensation

many dry-mix applications (e.g., tile adhesives, self-leveling compounds, repair mortars) require:

- ·rapid strength development

- ·dimensional stability

- ·low shrinkage or expansion to offset drying shrinkage

ecobinder is engineered to deliver

fast setting, high early strength, and controlled expansion